Bettonville specializes in designing and manufacturing of Diamond Cutting Laser Machines for cutting of natural diamonds and synthetic diamonds.

Bettonville's activities and products draw on over 100 years of tradition in development, innovation and manufacturing of diamond tools and machines for diamond industry of its predecessor, Bettonville NV of Antwerp, Belgium.

One of the most successful Bettonville products have been Diamond Sawing Blades for sawing of natural diamonds produced from the 1950s onwards. The quality of this product was unique in the gem-diamond industry and for decades Bettonville enjoyed for its Diamond Sawing Blades almost a complete monopoly in the market.

Other significant Bettonville manufacturing success included its automatic diamond bruting machines, which traded under the name MAXICUT™ from the 1980s. The concept of MAXICUT was patented worldwide and its appeal led to 8 further generations being developed to meet market demand.

In 1997, in partnership with I. Hennig, Bettonville established a sub-contracting diamond manufacturing factory in Visakhapatnam, India, known as WDM (Worldwide Diamond Manufacturers Pvt. Ltd.), employing more than thousand workers. The factory was exclusively equipped with Bettonville’sdiamond tools and machines and served to showcase all Bettonville products.

In 2001, Bettonville launched its newly developed COMBI Diamond Cutting Laser Machine - the first multi-tasking diamond cutting laser machine which enabled both sawing and shaping of natural gem quality diamonds - a global first in the gem-diamond market. The speed of diamond sawing using laser technology compared to speed of traditional abrasive diamond sawing, coupled with the precision and safety of laser cutting of any shape of natural diamonds, has since made diamond cutting laser machines indispensable for the gem-diamond industry.

In 2003, at the LASER 2003 World of Photonics Exhibition in Munich, Germany, Bettonville launched Ultrashape 5xs Diamond Cutting Laser Machine, its first industrial laser machine for 2-dimensional laser cutting aimed at both natural and synthetic, man-made diamonds. This machine global success has resulted in Bettonville continuously developing new diamond cutting laser machines and various measuring and positioning devices for natural diamonds and synthetic diamonds industries to meet demand.

Bettonville Ultrashape 5xs Diamond Cutting Laser Machines are still used by manufacturers of diamond products for tooling, optical, electronic and scientific research and jewelery industries.

Bettonville Ultrashape MK6 Diamond Cutting Laser Machine, newest version of Ultrashape 5xs machine, is widely used in production of CVD moncrystal diamonds for diamond coring, diamond slicing with narrow parallel kerf, smoothing of surfaces of diamond slices. It is also used for 2-dimentional diamond shaping, diamond anvils shaping, drilling of boreholes of variable profiles for diamond wire-dies and water-jet orifices, amongst other uses.

The common denominator for all these cutting techniques is the guaranteed safety of any precious diamond material and an excellent surface smoothness after processing – which in turn permits savings on post-processing effort and expense.

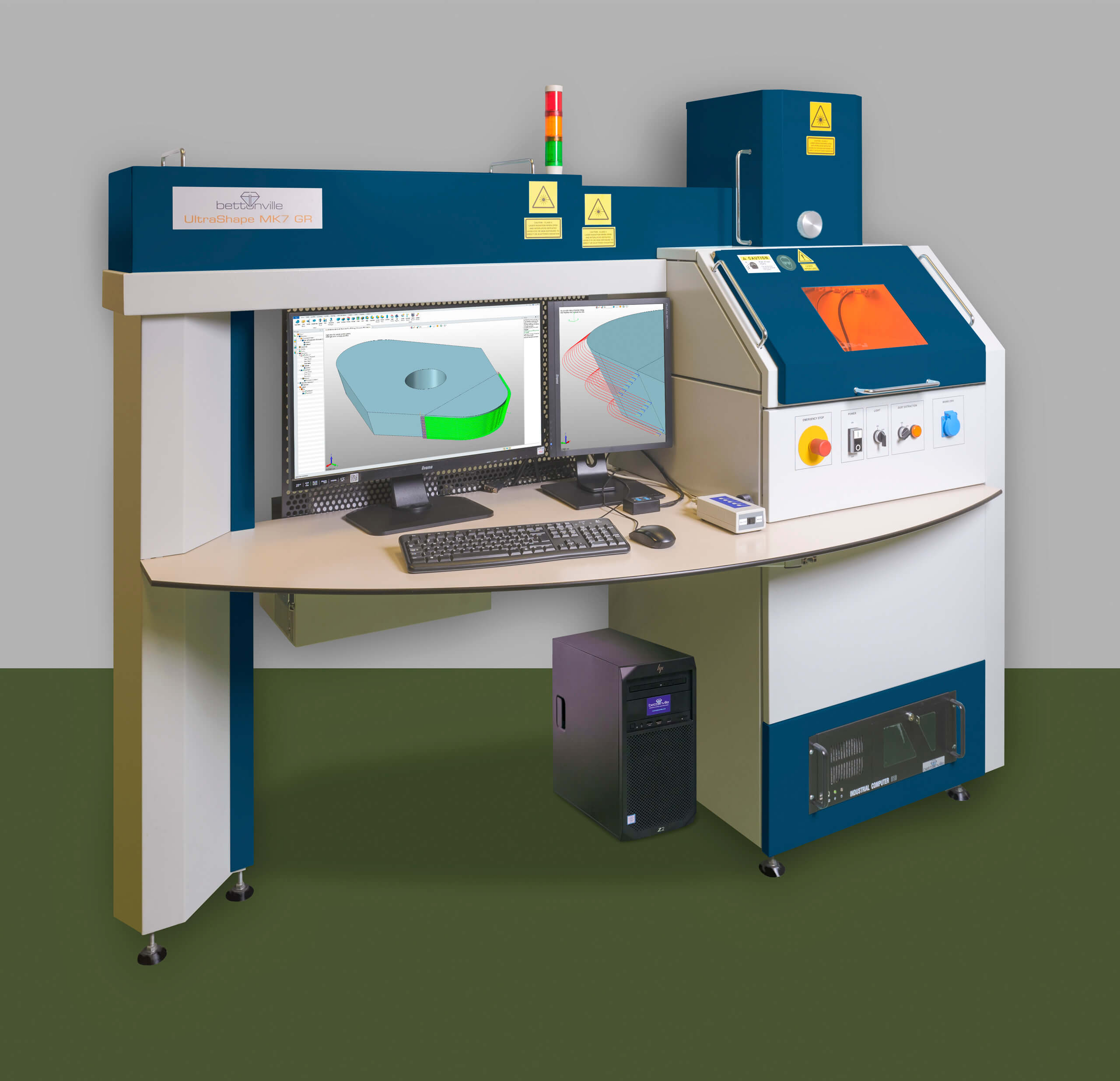

At recent trade fairs, GrindTech in Ausburg and LASYS in Stuttgart , leading trade fairs for laser machines technology in Germany, Bettonville launched its latest vanguard technology for the industrial market - Ultrashape MK7 Diamond Cutting Laser Machine, which enables 3-dimensional (3D) laser cutting of any diamond materials - once again, a market first.

Ultrashape MK7 Diamond Cutting Laser Machine offers users a full 5-axis machine with integrated CAD/CAM program, compatible with other CAD programs (Solid Works, Inventor, etc.)

This machine is aimed at small to medium sized diamond cutting factories engaged in manufacturing of short series, short delivery time synthetic diamond-tipped tools for a variety of applications in automotive, aviation, electronic and plastics industries.

Special attention in designing Ultrashape MK7 Diamond Cutting Laser Machine's capabilities has also been paid to the very exclusive needs of manufacturers of monocystal CVD diamonds for electronic and other industrial aplications.